SPD-V200 Strand Condition Monitor for Continuous Caster Professional

1 day ago - Services - Dhaka - 15 viewsOverview

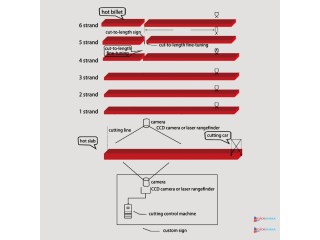

In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range during the production. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the breakout of steel in pouring process, surface and internal cracks and centerline deviation.

The measurement of the strand condition monitor

Roll gap value:

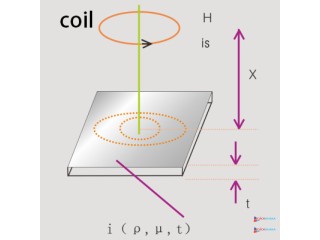

By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the roller bed of CCM.

It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster.

Arc condition of guide roll:

Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guide roller.

Guide roll rotation:

Can know whether each guide roll can rotate freely by measuring.

Water spray pressure:

The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal.

The main components of the strand condition monitor

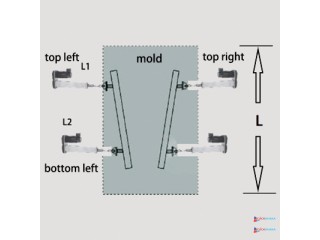

1. The main body of the strand condition monitor used to measure the continuous casting sector

2. The connecting chain for strand condition monitor and dummy bar

3. The storage rack chain of strand condition monitor

4. Battery charger: 24V 5A

5. Calibration equipment

6. Remote control

7. Laptop

8. Printer

9. Data communication cable

The technical parameter

1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements)

2. The measurement accuracy of roll gap: 0.01mm

3. The arc measurement range: ±80°

4. The arc measurement accuracy: 0.01°

5. The spray measurement range: 0-10 level

6. The spray measurement accuracy: ±1

7. The battery usage times: >3 times

SCM

Roll gap sensor Rotation sensor Guide roll arc sensor